Pipingprojects.us is one of the major Flanges Manufacturer in USA. We manufacture and offer many types of flanges, including lap joint flanges, weld neck flanges, orifice flanges, slip-on flanges, and others. We employ a variety of materials to make our high-quality flanges. Alloy Steel Flanges are mostly constituted of chromium, molybdenum, and nickel in their chemical composition. Chrome Moly Flanges are known for their superior corrosion and oxidation resistance. We are a top Flanges Supplier in USA.

What Are Flanges?

A flange is essentially a method of connecting pipes, valves, pumps, and other equipment to form a piping system. It also provides easy access for cleaning, inspection, or modification. Flanges are usually welded or screwed into the system and then joined with bolts.

Importance of Flanges in Various Industries

Flanges are indispensable in industries such as oil and gas, chemical processing, water treatment, and power generation. They ensure the safe and efficient transport of fluids and gases by maintaining the integrity of the piping systems.

Types of Flanges

Understanding the different types of flanges is essential for selecting the right one for your application. Here are the most common types:

Weld Neck Flanges

These flanges are designed to be welded to the pipe. They have a long neck that helps to reduce the stress on the flange by transferring the stress to the pipe. Weld neck flanges are ideal for high-pressure applications.

Slip-On Flanges

Slip-on flanges are easy to install and are simply slipped over the pipe and then welded both inside and outside to provide strength and prevent leakage. They are suitable for low-pressure applications.

Blind Flanges

Blind flanges are used to close the ends of piping systems. They are also used for pressure testing of fluid flow through pipes or vessels. Blind flanges are among the most highly stressed flange types and must handle the highest pressure conditions.

Socket Weld Flanges

These flanges are typically used for smaller sizes of high-pressure pipes. The pipe is inserted into the socket end and welded on the outside. This provides a smooth bore and better fluid flow within the pipe.

Lap Joint Flanges

Lap joint flanges are used with stub end fittings. They are typically used in systems that require frequent dismantling for inspection and cleaning. These flanges are not welded or screwed to the pipe, making them easy to install and remove.

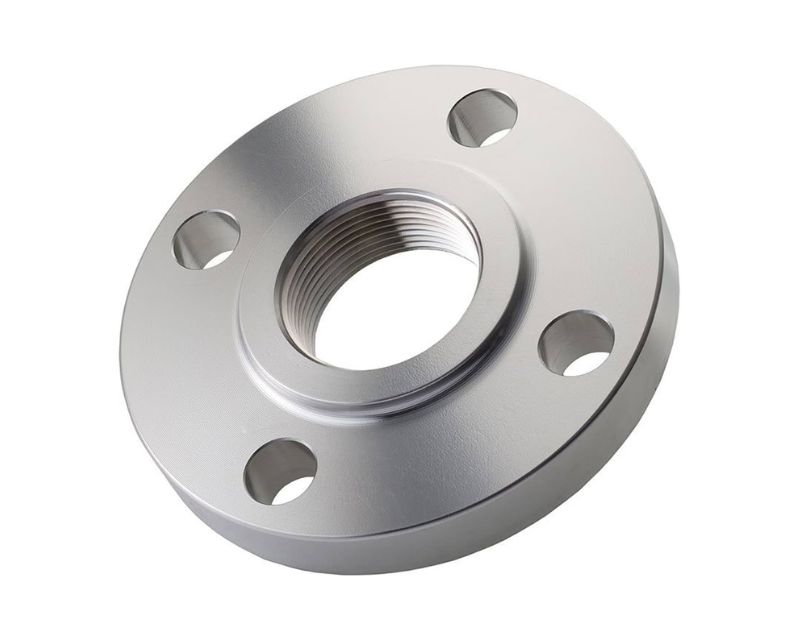

Threaded Flanges

Threaded flanges are screwed onto the pipe, making them ideal for systems where welding is not possible. They are used mostly in low-pressure, non-critical applications.

Materials Used in Flanges

Flanges can be made from a variety of materials depending on the application requirements.

Stainless Steel

Stainless steel flanges are corrosion-resistant and suitable for high-temperature and high-pressure environments. They are commonly used in chemical, petrochemical, and food processing industries.

Carbon Steel

Carbon steel flanges are known for their durability and strength. They are used in industries where flanges need to withstand high pressure and temperature, such as in oil and gas pipelines.

Alloy Steel

Alloy steel flanges offer enhanced mechanical properties and better resistance to corrosion. They are used in applications requiring higher strength and resistance to wear and tear.

Special Alloys

Special alloy flanges, such as those made from Inconel or Monel, provide excellent corrosion resistance and are used in highly corrosive environments like marine and chemical industries.

We are Flanges Supplier In:

Flanges Supplier in California

Manufacturing Process of Flanges

Flanges are manufactured through several processes, each ensuring the desired strength, durability, and performance.

Forging

Forging involves shaping the metal using compressive forces. It enhances the strength and durability of the flanges, making them suitable for high-pressure applications.

Casting

Casting is the process where molten metal is poured into a mold to create the desired shape. This method is cost-effective for producing complex shapes but may not be as strong as forged flanges.

Cutting and Machining

This involves cutting the flange from a larger piece of metal and then machining it to the desired shape and size. This method allows for precise dimensions and smooth finishes.

Applications of Flanges

Flanges are used in various applications across different industries due to their versatility and reliability.

Oil and Gas Industry

In the oil and gas industry, flanges are used in pipelines, refineries, and offshore drilling rigs to ensure secure and leak-proof connections.

Chemical Industry

Chemical plants use flanges to connect pipes carrying aggressive chemicals, ensuring safety and preventing leaks.

Power Generation

Flanges are crucial in power plants for connecting pipes that carry steam, water, and other fluids necessary for power production.

Water and Sewage

Flanges are used in water treatment and sewage systems to connect pipes and ensure the reliable transport of water and waste.

Benefits of Using Flanges

Why are flanges so widely used? Here are some key benefits:

Easy Assembly and Disassembly

Flanges allow for quick assembly and disassembly of piping systems, which is essential for maintenance and repair.

Leak Prevention

Properly installed flanges provide a tight seal, preventing leaks and ensuring the integrity of the piping system.

Strength and Durability

Flanges are designed to withstand high pressures and temperatures, providing long-lasting performance in demanding environments.

Standards and Specifications for Flanges

Flanges must meet specific standards to ensure safety and performance.

ASME Standards

The American Society of Mechanical Engineers (ASME) sets standards for flange dimensions, pressure ratings, and materials.

DIN Standards

The German Institute for Standardization (DIN) provides guidelines for flange dimensions and materials, commonly used in Europe.

ANSI Standards

The American National Standards Institute (ANSI) sets standards for flange sizes, pressure ratings, and materials used in the US.

Future Trends in Flange Technology

The flange industry is evolving with new technologies and materials.

Advances in Material Science

New materials with better strength, corrosion resistance, and temperature tolerance are being developed to enhance flange performance.

Improved Manufacturing Techniques

Advancements in manufacturing techniques, such as 3D printing, are making it possible to produce flanges with complex shapes and improved properties.

Flanges Manufacturer In USA

We are a high-quality Flanges Manufacturer. These flanges can be manufactured by either forging or casting. Esteemed stainless steel flange manufacturers provide these components for reinforcing or connecting beams and columns. Installing stainless steel pipe flanges is tailored to the appropriate flange type, ensuring a precise and secure fit for smooth integration into the piping network.