Unveiling the Uses and Advantages of PVDF Mirror ACP Sheets

The use of aluminium composite panels has changed the arc of modern architecture giving liberty to architects and designers to explore their creativity. The acp sheet design is not only limited to exterior cladding or wall partitions but its applications are as vast as the creative idea goes. However, a lot goes into making ACP sheets one of the most sought-after products in the world of building and architecture. One of the most compelling elements is the aluminium itself which is loaded with features like durability, flexibility, lightweight and of course weather resistance, surpassing the expectations of traditional cladding materials.

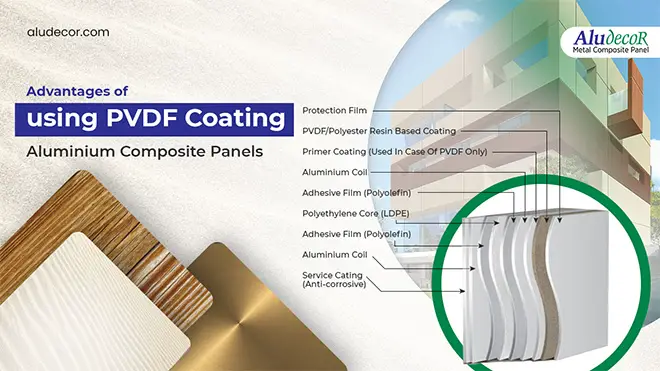

This is not all, as manufacturing of aluminium composite panels does not only depend on the aluminium but the paint coating also matters. The pvdf coating that goes on the top of the panels ensures that it stays corrosion-resistant and shine-worthy for years to come. So what is PVDF paint? Let’s take a look.

What Is PVDF Surface Treatment in Aluminium Composite Panels?

PVDF or polyvinylidene fluoride is a pure thermoplastic fluoropolymer that is non-reactive and has several advantages. It has low weight and low thermal conductivity making it a common material in chemical processing equipment. One of the best features of PVDF is that it has exceptional wear and abrasion resistance alongside being ineffective to most chemicals and solvents.

It has applications across industries including chemical, electrical and energy-related and is mostly used as resin-based liquid surface treatment. This is why pvdf coated acp is recommended to achieve that long-lasting shine and colour in exterior cladding solutions.

What Are the Advantages of PVDF Mirror ACP Sheets?

The mirror ACP sheets, as the name suggests, have a mirror finish effect giving it a shiny look. So how does PVDF paint coating contribute to keeping these sheets looking new and shiny, let’s take a look,

Aesthetic Appeal is Enhanced

The coatings of PVDF paint are popular for their high-quality finish and vibrant colour retention. When this liquid treatment is applied on a mirror acp sheet, it helps in creating a sleek and reflective surface that enhances the appeal of the material. That is why, aluminium composite panel with mirror effect uses PVDF coating for the visual appeal of the architectural design.

Weather Resistance with Durability

As already mentioned PVDF coating has excellent resistance against harsh weather conditions. So, a mirror acp sheet has a multi-fold benefit with this paint coating. From harsh UV radiation to moisture accumulation and temperature fluctuations, this paint forms a protective layer saving the rich colour pigments of the ACP sheets giving it a long-lasting mirror shine.

Easy Cleaning & Maintenance

PVDF coating on Mirror ACP sheets makes them easy to clean and maintain. Accumulation of dust, and dirt is normal for mirror-finish ACP sheets in interior applications. However, the paint coating with polyvinylidene fluoride gives the sheets a smooth surface with no crevices for dust and dirt to get trapped in making it easier to clean and maintain.

Fire Resistant

Aluminium does catch fire, however, with pvdf coated acp, the metal’s fire-resistant capabilities increase as PVDF has the ability to self-extinguish and generates little smoke in the event of a fire. Thus, it contributes to the FR aluminium composite panels making it resistant in the occasion of a fire.

Parting Words

Overall, the PVDF paint coating on mirror ACP sheets combines aesthetic appeal, durability, weather resistance, and easy maintenance, making them an excellent choice for modern architectural designs where reflective surfaces and functionality are desired.