We Can Water Jet Cut Anything Stone, Porcelain, Metals & more!

Water Jet Cut Splashbacks, Made In Melbourne

Using state-of-the-art laser templators, we produce highly defined .dxf cad files of your design. From here, we drop the file into our waterjet, where it’s then able to cut out exactly what the laser templator had measured up. As an example, you may have a crooked wall that requires an overlay. The laser templator will pick this up, and instead of cutting the back of your bench straight, our team will cut it to the shape of the crooked wall through lasering. This then sits up against the final result nice and flush. Ultimately, this type of technology gives our team the ability to create highly refined, precise CAD drawings of your vision. Combining it with DXF drawings, the end-result is backed by a several-step, technical process.

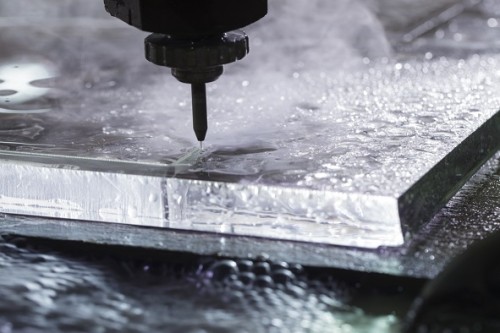

What Is Water Jet Stone & Porcelain Cutting?

Through this highly refined process, our team creates exceptionally crafted products – including water jet cut splashbacks, benchtops, and many more concepts. A major advantage of this method is that it’s based around cold-cutting techniques. This means that, during the action of water jet cutting and laser drawing, the product is not put under unnecessary stress or pressure. This is especially useful when we need to cut extremely complex shapes that demand accuracy. Best of all, we can utilise a fine tip radius to create the highest water jet cutting detail possible.