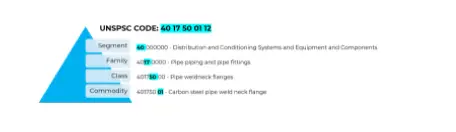

If you have experienced challenges in the past to ensure good MRO data classification, then you are certainly not alone. Many well-known companies within the procurement sector find MRO data classification to be a complex process. The effectiveness of the MRO material master can be enhanced only through accurate classification of all the commodities and products according to a classification system that is regarded as an industry standard. Common classification systems for MRO include UNSPSC and eCl@ss. The best classification systems always adhere to a hierarchical structure and group all the items into proper categories that can then be mapped and related to the internal commodity structures of the company.

It is common for the asset extensive organizations to focus greatly on the functioning of the MRO supply chain since the various MRO items are vital for ensuring the reliability and proper functioning of the plant. By using an excellent data classification system, it is possible to work with robust spend analytics and better procurement practices.

Here are the best practices for MRO data classification.

High data quality

Superior data quality should be maintained at all costs, without which it won’t be possible for companies to benefit from MRO data classification. This means that duplicate part numbers should be removed and standard systems for product classification should be followed. This can help in connecting the nonstandard classifications with the OEM part numbers. Such practices can improve the value of the inventory.

Offering the best support to the suppliers

When it comes to product standardization and the improvement of the MRO process, the suppliers can be of great help. Therefore, by supporting the suppliers it is possible to ensure a good deal of cost reduction. Indeed, plant maintenance teams are always insisting on standardization practices. However, such efforts should be internally supported by the procurement team as well as by the suppliers. This can create a lot of value within the MRO industry. MRO distributors can work with manufacturers and integrators to provide a high level of services and a great deal of functional knowledge that can help their client organizations.

Complexity should be removed from MRO management

One of the major obstacles of smooth MRO data classification is of course the presence of complexity at its different stages. It is important to standardize the product’s specifications and ensure the proper functioning of the supply base to cut down on complexity. When you are working with a handful of strong suppliers, you can support the OEMs and the MRO distributors that they must have from the procurement team. Efficiently managing relationships with the supply chains can be beneficial in many ways.

Efficient mapping of key processes

The supply chains and the organizations looking to work with MRO should maintain a proper view of the relevant maintenance processes so that they can detect the sources of complexity quickly and have them resolved. In many cases, businesses ignore such complexities but they should be dealt with immediately. This mapping of processes can ease MRO data classification.

Know more about mro data classification