A switchboard is a device that distributes electricity from single or numerous sources to various smaller regions of use. It is a collection of one or more panels, each containing switches for rerouting electricity. A switchboard comprises multiple interconnected components, the primary and distribution portions being the most frequent. Occasionally, these two parts are replaced by a combination section that performs the functions of both primary cells. Additionally, switchboards may have an auxiliary section for devices that cannot fit in the same section as other devices.

5 Reasons to Switch to Thermosetting Plastic Switches

Before the advent of the plastic switches that we are familiar with today, switches were fashioned of porcelain. Bakelite, an early form of brittle plastic made from formaldehyde and phenol, was introduced shortly after. In recent years, thermosetting plastic switches have become more prevalent.

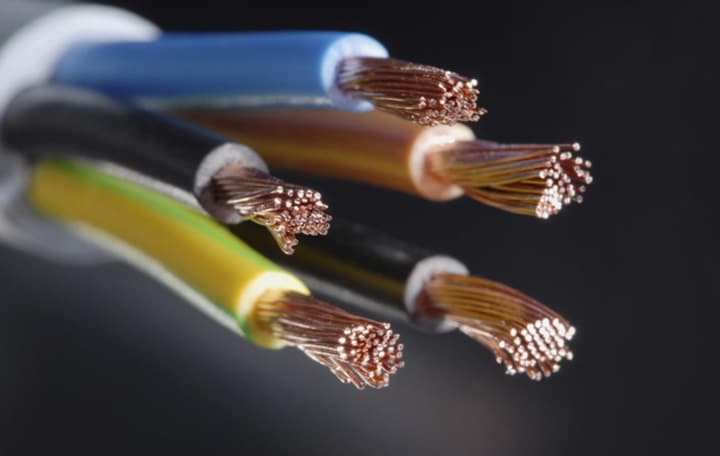

Typically, switches are used to activate electric lights, electrical equipment, or electrical outlets and switch mounting plates, covers, and seals in electrical lines. Both must protect the user from electric shocks. Unsurprisingly, switches are constructed from materials that transmit electricity poorly, such as porcelain, Bakelite, and thermosetting plastic.

Leo Baekeland, a Belgian chemist, invented the thermoset plastic in 1906. Baekeland developed the plastic by combining phenolic resin, formaldehyde, and heat. It is a polymer that cures permanently into a hardened form. A thermoset is a thermosetting polymer that has been cured. Once cured, a thermoset resin cannot be remelted and molded. Initially, Baekeland's discovery was used to kitchenware, toys, and electronics. Additionally, the usefulness of thermosets was increased, enabling their usage in a wide variety of industrial applications.

The following are some of the advantages of using a thermosetting plastic switchboard in Eltham.

A conductor of electricity with defects

This is the most critical characteristic of electrical switches, as well as a required one. Thermosetting plastic is an inefficient conductor of electricity.

Resistant to structural deterioration and long-lasting

When thermosetting plastic is cured throughout the manufacturing process, it develops an irreversible toughening property. This is an important factor to consider and is preferred when it comes to electrical switches. It is not self-crackable, but external and deliberate force can cause it to crack.

Chemical and Corrosion Resistant

Electrical appliances are safe from a safety standpoint since they are resistant to chemicals and corrosion.

Heat Resistant

Additionally, thermosetting plastic is ideal for electrical switches. You do not want your buttons to melt rapidly, as this may result in short circuits and fires.

Lightweight

With all of these amazing qualities, being lightweight is a bonus. The use of thermosetting plastics in various industries is unsurprising, including autos, medical devices, metal finishing, transportation, aviation, aerospace, chemicals, and computers. With all of these wonderful benefits, now is the time to switch to thermosetting switches. They are extremely durable, having been tested to withstand over 100,000 clicks. The switches include a one-of-a-kind luminous strip that acts as a guide and glows in the dark. The Premium Range includes modular switches, sockets, fan regulators, light dimmers, shaver sockets, card-operated switches, doorbells, telephone sockets, computer sockets, and television sockets.