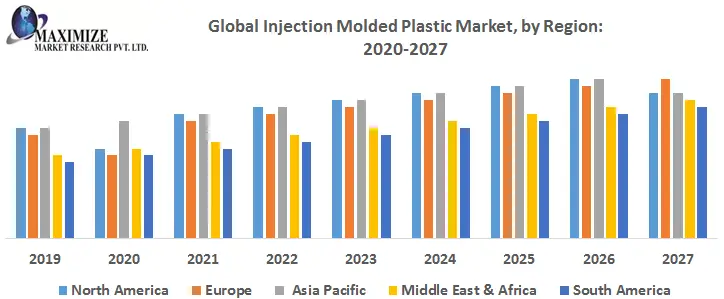

Global Injection Molded Plastic Market was valued at US$ 326.66 Bn in 2017 and is expected to reach US$ XX Bn by 2026, at a CAGR of XX % during a forecast period.The objective of the report is to present a comprehensive assessment of the market and contains thoughtful insights, facts, historical data, industry-validated market data and projections with a suitable set of assumptions and methodology. The report also helps in understanding Injection Molded Plastic market dynamics, structure by identifying and analyzing the market segments and project the global market size. Further, report also focus on competitive analysis of key players by product, price, financial position, product portfolio, growth strategies and regional presence. The report also provide PEST analysis, PORTER’s analysis, SWOT analysis to address question of shareholders to prioritizing the efforts and investment in near future to emerging segment in Injection Molded Plastic market.Injection molded plastics are utilized in production of advanced complex and intricate shaped parts for exactness with least waste. Due to these advantages, injection molded plastics are used in manufacturing process of automotive elements, interior wrapping, and miscellaneous assembly components. It is also used in packaging industries to produce packaging parts & components to increase the aesthetics and consumer friendliness of the packaging products. Injection molded plastics are extensively preferred in building and construction purposes due to the strength, durability, and appearance of the injection molded plastic parts. In building and construction industry, these plastic parts or components are majorly working for piping systems, insulation, wall board, and roofing purposes. Healthcare industry is the fastest growing sector for injection molded plastics industry during the given time frame. Blood sample analysis cuvettes, parts of medical devices, and pregnancy test devices, housings for needles are few of the segments, owing to the lightweight, cost-effectiveness and easy serializable properties of injection molded plastic.Factors such as low production rate and faster production process would boost the growth of the injection molded plastic market. Additionally, the process has ability to use several types of raw materials simultaneously to manufacture plastic parts. Furthermore, technological & innovative advancements in injection molding process, where robots are used for performing different operations, such as finishing and assembling injection molded parts and loading components into the injection molding, would raise the growth of the market.Rise in demand for consumer goods, processed food, and beverages in emerging markets & plastics acquired more importance in different packaging industries owing to their durability, temperature resistance and low cost. Due to such beneficial aspects, injection molded polypropylene, ABS, HDPE and others are used in different packaging applications, such as caps and closures, totes, industrial shipping pails, and crates. Such widespread scale applications of injection molded polypropylene, ABS and other similar materials are driving the growth of the global injection molded plastics market during the forecast timeframe.Growing concerns regarding toxic issues affecting to petrochemicals along with reducing crude oil reserves have been driving the development of bio-based polymers. Government rules & regulations restricting consumption of petrochemical-derived polymers in certain applications such as food packaging and medical devices are likely to further incentivize the production of bio-based polymers.Based on raw material type, Polypropylene holds as the largest raw material segment and accounted for just over 35% of total demand in 2017 due to its rising consumption in household appliances, automotive components, and packaging applications. Growing penetration of polypropylene finished products in food packaging, protective caps in electrical contacts, and battery housings is expected to contribute to the growth of the segment over the forecast period.In terms of application, the packaging segment of the molded plastics market is likely to grow at the highest CAGR during the forecast timeframe. Automobiles, pharmaceutical, chemical, and personal care industries are main consumers of molded products, which are used to produce bottles, packaging films, cans, and containers. In terms of revenue, automotive & transportation application holds the highest growth rate, increasing with an estimated gains of over 5.9% up to 2026. Polymers offer flexibility in design to manufacture vehicle component compared to steel substrates, which may positively affect automotive plastics market demand over the forecast period.Globally, Asia Pacific dominated the global demand and accounted for highest market in 2017. Increasing infrastructure funding, coupled with growing automobile demand in countries such as China, India, Indonesia, and Malaysia, are likely to propel the regional market. North America dominant the injection molded plastic market demand, is set to grow at more than 4.95 % CAGR up to 2026. Rise in Automobiles packaging demand due to increase in processed food & alcohols demand coupled with building & construction industry expansion are expected favorable factors to drive demand.The report study has analyzed revenue impact of covid-19 pandemic on the sales revenue of market leaders, market followers and disrupters in the report and same is reflected in our analysis.

Disclaimer: This is a user generated content submitted by a member of the WriteUpCafe Community. The views and writings here reflect that of the author and not of WriteUpCafe. If you have any complaints regarding this post kindly report it to us.