Crane weight indicators are essential tools that play a critical role in optimizing precision, efficiency, and safety in lift operations. They provide accurate measurements of the weight of the load, prevent overloading, and ensure that the crane is stable and secure during the lift. In this article, we will explore the multifaceted uses and advantages of crane weight indicators.

Improving Precision in Lift Operations

Crane weight indicators are capable of providing very accurate measurements of the weight of the load that is being lifted. This means that the crane operator can be sure that they are lifting precisely the amount of weight that they need to, which is especially important in situations where the load is very heavy or delicate. By using a crane weight indicator, the operator can lift the load with greater precision and accuracy, thereby reducing the risk of accidents and damage to the load.

Additionally, crane weight indicators can also help optimize the crane's performance and reduce wear and tear on the machinery. By ensuring that the load is being lifted at the appropriate weight, the crane can operate more efficiently, which can lead to cost savings over time. Overall, the use of crane weight indicators is a simple yet effective way to improve lift operations.

Increasing Efficiency in Lift Operations

Crane weight indicators improve efficiency in lift operations by providing accurate measurements of the load's weight. This enables the crane operator to lift the load more quickly and with less effort.

By using a crane weight indicator, the operator does not have to spend time guessing the weight of the load and adjusting the crane accordingly. Instead, they can rely on the weight indicator to provide them with accurate information and make the necessary adjustments quickly and efficiently.

In addition to improving efficiency, crane weight indicators also enhance safety in lift operations. By providing accurate weight measurements, they prevent overloading of the crane, which can lead to accidents and injuries.

This makes crane weight indicators an essential tool for any lifting operation that involves heavy loads. With their reliable and precise weight measurements, crane weight indicators help ensure that lift operations are carried out safely and efficiently without unnecessary risks or delays.

Enhancing Safety in Lift Operations

Perhaps the most significant benefit of crane weight indicators is their contribution to safety in lift operations. These indicators are designed to prevent overloading, which is one of the most common causes of accidents in lift operations.

When a crane is overloaded, it becomes unstable and can tip over, causing severe damage and injury. Crane weight indicators ensure that the crane is not overloaded and that the load is evenly distributed, thereby reducing the risk of accidents and ensuring that the lift is carried out safely.

Types of Crane Weight Indicators

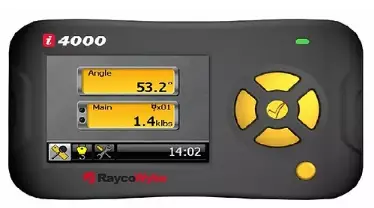

Crane weight indicators come in a variety of types, each with its unique advantages. Some of the most common types include electronic, hydraulic, and mechanical indicators. Electronic indicators are among the most accurate and reliable, as they use advanced sensors and digital displays to provide precise measurements of the weight of the load.

Hydraulic indicators are also highly accurate and reliable, but they require more maintenance than electronic indicators. Mechanical indicators are the most straightforward and most affordable, but they are also the least accurate and reliable.

Other Uses of Crane Weight Indicators

In addition to their primary functions, crane weight indicators can be used for a variety of other purposes. For example, they can be used to measure the tension in the crane's cables, which is essential for ensuring that the wires are not overstressed and that they do not break during the lift. They can also be used to monitor the crane's angle and position, which is essential for ensuring that the crane is stable and secure during the lift.

Conclusion

Crane weight indicators are essential tools that are critical for ensuring precision, efficiency, and safety in lift operations. By providing accurate measurements of the weight of the load, preventing overloading, and ensuring that the crane is stable and secure during the lift, crane weight indicators play a crucial role in reducing accidents, damage to the load, and injury to workers.

Crane weight indicators come in a variety of types, each with its unique advantages, and can be used for a variety of other purposes as well. Whether you are a crane operator or a construction worker, understanding the importance of crane weight indicators and how they can help you carry out your work safely and efficiently is critical.

Your One-Stop Crane Safety Solutions Provider in the US

Are you looking for advanced crane safety devices such as a Rated Capacity Indicator or Anti two block switch for your crane equipment? Head over to Crane Warning Systems Atlanta’s website today. The company is the most reliable and reputable crane safety device seller in the US. They have provided original and branded RaycoWylie crane warning indicators to crane users nationwide.

Author’s Bio

The author of this post is a senior manager at Crane Warning Systems Atlanta. He is highly experienced in crane safety methods and strategy operations. He regularly shares his insights and wisdom with the company’s blog readers to keep them aware of crane risks and their solutions.