If you want to design custom apparel, there are many ways to go about it. Methods used for custom printing include screen printing, embroidery, DTG, and sublimation, to mention but a few. Each of these methods is unique regarding output and the work put in.

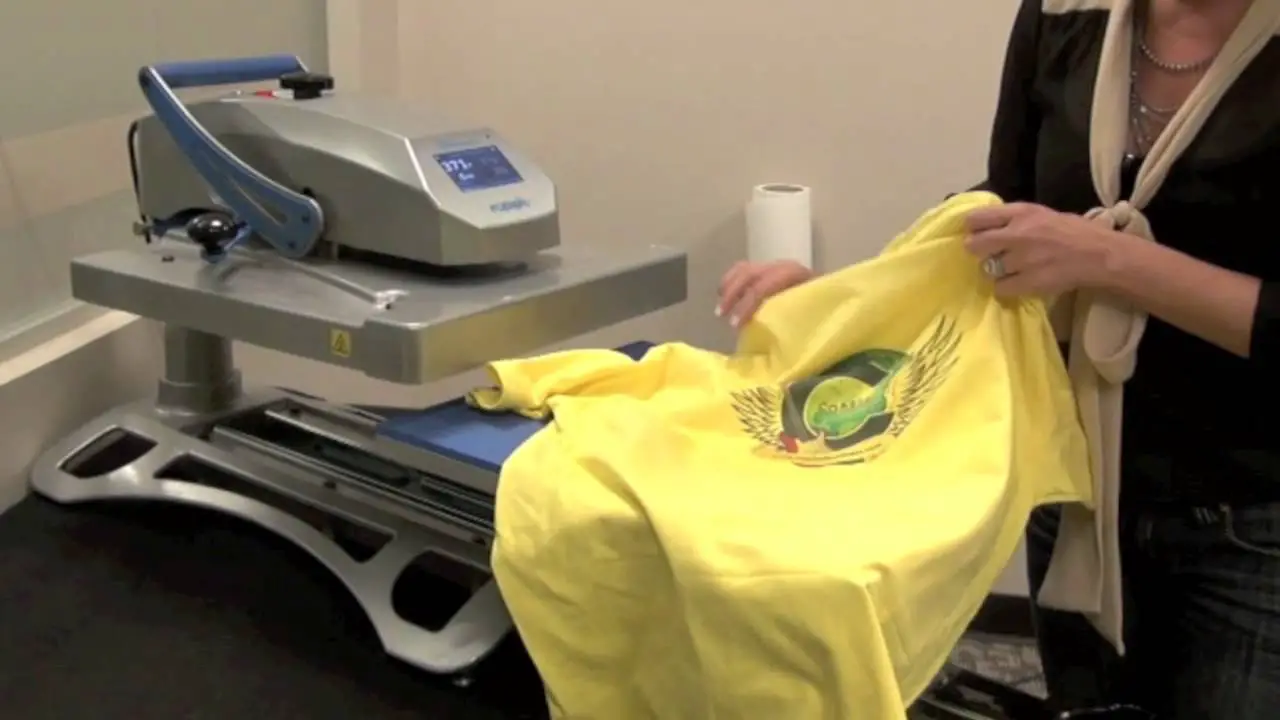

All other methods are excellent for custom printing. However, let us focus on heat transfer, also known as thermal printing. It’s a method of printing that allows you to print your design onto a piece of clothing or object.

Since there are many types of thermal transfer, how do you select the best?

Factors to Consider When Selecting the Best Heat Applied Transfer

Before anything else, ensure you are using a solid heat press. Purchasing a heat press needs you to pay attention to the work you intend to do. All heat presses are different, and it is vital to know why one is better than the other.

You don’t want to lose clients because of inadequacies caused by poor heat transfer. Here are a few factors to consider so you’ll know what to choose and when.

- Quantity

When choosing a thermal transfer type, you have to know how many shirts or objects you need to be printed. For example, if you deal with five shirts or less, the most appropriate transfer would be vinyl.

The cost also depends on the number of items you need to be worked on. More than five shirts require screen printing because cutting your own designs in all these shirts will cost you time and money. For easier execution and fast turnaround, choose screen printing.

- Artwork

The details in your design influence the type of heat transfer you use. If you choose vinyl, remember that you’ll have to cut the design and do the weeding manually. Weeding areas with intricate details can get frustrating and time-consuming.

Also, consider your cutter. If your cutter cannot conveniently cut small details and takes a short time while doing it, you need another method. Moreover, one shirt might have 100 names on it. In this case, screen printing is the way to go.

- Amount of Colors

The colors needed in your custom-printed items determine the heat transfer method you choose. More colors will lead you towards screen-printed transfers.

With vinyl, you have to individually cut designs for each color, do weeding, and apply heat each color at a time. This process will take you longer, especially if you are working with several items. Spot coloring and full coloring also play a part in selecting the heat applied transfer.

- Fabric Content

Screen printed and vinyl transfers go on different types of fabric. It depends on the stretchability and heat sensitivity of the apparel. Knowing the fabric content will guide you appropriately on heat-applied transfer.

The custom printing process is exciting because you can choose how your shirts or apparel will look. Thermal printing is an excellent method of transferring designs onto your desired items. As long as you select the right transfer, the result will be stupendous.

0