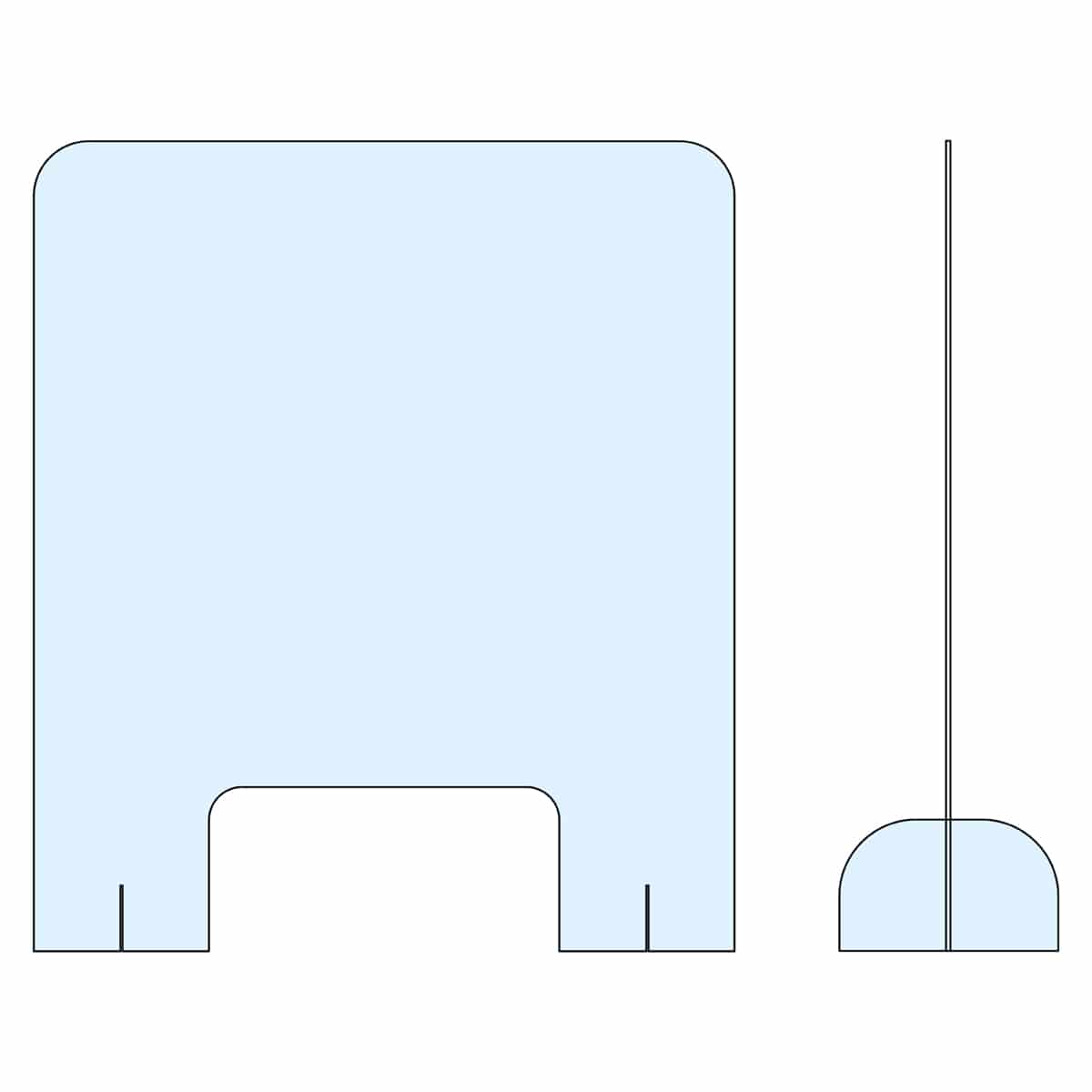

Hygiene Screen with cutout – 620x740mm – 10mm acrylic

First Display based in Edinburgh supplies Signs Display, large format printing, estate agent boards, banners, a-board, signage, display systems throughout the UK.

Table of content:

- Is Hygiene important for pandemics?

- What are the advantages of a hygiene screen?

- Why is our design best?

Is Hygiene important for pandemics?

The hygiene. when cutting th laser ohms, within the material may be high voltage. Therefore, it is not recommended to glue such surfaces. At the same time, laser processing has advantages. Thanks to this method, it is possible to perform the work with maximum accuracy, and the quality of the cuts themselves remains at a height. Furthermore, the use of laser requires less waste than when use and saws. The molded information sign in the cutting area heats up quickly. This is due to the low thermal conductivity. It should be processed at high speeds and at a minimum depth of the cut layer. To drill extruded plexiglass, drilling machines, both stationary and mobile, and special drills for light metals made of high-speed steel are used. Before processing the material, the tools must be specially sharpened. The resulting hole should have smooth edges to avoid cracking the plexiglass.

What are the advantages of a hygiene screen?

If a deep hole is to be drilled, then during operation it is necessary to remove the drill several times and clean it of chips. This measure also helps to protect the material from strong heat. Any metal twist drills can be used for injection-molded plexiglass. To prevent internal stress during machining, the material and cutting tools must be cooled with compressed air or lubricating fluids created for this purpose. The display signs of the processing of cast and extruded plexiglass is different, although there is a certain similarity of work with these materials. In both cases, it is recommended to use “related” adhesives for gluing sheets, this will help to create the most durable and resistant to external influence seam. To ensure that the junction of the two parts with an overlap or butt is neat and colorless, it is better to use PMMA glue made on the basis of polymethyl methacrylate.

Why is our design best?

The design is before work, cast plexiglass should first be annealed at a temperature of and cooled naturally. This will relieve the internal stress of the material. The use of welding is justified in those cases when it is necessary to UK signboards a blank for molding products of non-standard shape, to form thickenings, and to make fastenings of the linings. Cast plexiglass is processed at higher temperatures, up to. Relieve internal stress by thermal grinding of the finished part. Extruded plexiglass can be glued not only to each other but also to other materials. In any connection, the seam will be reliable and durable. It is advisable to subject the sheets to heat treatment before starting work. As solutions for gluing plexiglass, you should choose polymethyl methacrylate in a volatile solvent, with dimethylaniline. In the latter case, the composition of the substance should be diluted with benzoyl peroxide just before work. Also used are epoxy, polyester, polyurethane types of glue under the first display.