System administration, or CNC in JDE speak, is a high demand, low supply skill set. Sometimes it feels like a finite group of individuals with very few new additions. So traditionally when a business replaces or adds to their CNC Administration skill sets they really only have three choices:

- Hire a full-time CNC as an employee.

- Hire an independent contractor or consultant for a finite period.

- Outsource all or a subset of CNC need to a Managed Service Provider.

All three are resource-based types of choices. There may be situations where any of the three are valid options. However, there will be situations where none are good options. Over the last five years, the term “as-a-service” has become more popular. Many companies are moving away from a resource-based or ownership model to a service-based model for infrastructure (IaaS), software(SaaS) and platforms (PaaS). All involve physical hardware or digital software. The next wave will be companies acquiring

Lower cost

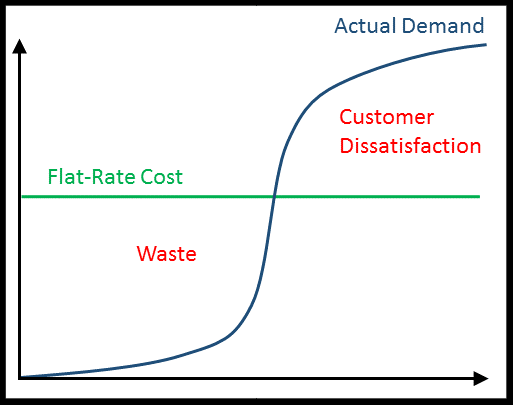

Just like when acquiring infrastructure or software, a company has had to pay in units of one for hiring human resources. We need two servers, one JDE installation with 100 licenses, one CNC, two developers, etc. Unlike hardware and software however, human resources generally want to work full-time in most cases. Of course the demand for this resource supply rarely comes in fixed units requiring one unit of supply over an hour, day, week or year. The demand usually varies across each of these units of time. Sometimes going from zero to well over 1 unit of demand. So the only solution is to have enough resources to meet the maximum demand regardless that it may not be needed all the time.

Actual Demand:

If you only really need 1-2 units over a year, you have to pay for 2. Costs will be much higher. Trying to match demand is impossible as if you pay for only 1 unit you will face many dissatisfied customers. The bottom line is you go through a continuous cycle of underutilized resources or dissatisfied customers as shown in below graphic.

Using a service provider that provides CNC tasks as a service has major advantages. You only pay for the task or service when it is used. This helps meet the demand at a lower cost relative to meeting the demand using a resource-based approach. The second graphic shows how this will lower cost by eliminating wasted resource time without negatively impacting customers.

Better matching skills to demand

The demand for CNC include various tasks. Some are package build/deploys, data refresh, troubleshooting issues. Larger tasks/projects may be upgrading to a new JDE version or tools release. Tasks range from routine requiring very basic CNC skills to very advanced requiring high level of skills and years of experience. Some may only require 1/2 hour of effort and others may require many hours or weeks.

In a resource-based approach the same resource will typically need to meet the demand for routine basic tasks and advanced tasks. The demand for CNC is usually not high enough to warrant hiring multiple resources with varying degrees of skills and experience and using the work to build experience and skills from entry level to senior level. As a result, demand for basic skills can disrupt the tasks that require higher level skills, or the existing skills may not meet some high level or advanced tasks.

A service provider that provides CNC as-a-Service can invest in the resources at various skill and experience level and match the right skill to demand as required. This will increase efficiency, productivity and lower costs.

Increased productivity

Many companies that use JD Edwards EnterpriseOne have one to a team of Full-time On-Premise CNC based on their size and needs. This approach may be the best one for them. However two reasons may boost their team's productivity using a hybrid approach by adding some level of CNC as-a-Service.

The work doesn't fit a traditional work schedule.

24/7 Nature of CNC work – CNC doesn't always fit into a 8 to 6 window. Some tasks need to be done when the system is not being used or when transactional volume is low. This may be 2 AM or over a weekend. Using overtime hours or scheduling resources for off-hours work may not be sustainable. Most individuals, especially if they have a high demand, low supply skill set will desire to work during standard business hours, but still work off-hours when needed. However, when off-hours is built into the tasks like CNC, it isn't just an occasional need.

On Demand vs. Project Work

When an organization's CNC resource or team is composed of Senior level skills they will need to constantly jump from project work to routine basic work. From work that helps the business generate revenue or profit, to work that helps keep the current system running. Tasks that require keeping the current system running tend to come at any time and may need resolution in real-time, so usually project work is put on hold to address the daily needs. The negative impact of constant task switching has been reported for some time with studies finding a loss of twenty-three minutes for each switch. The result is that critical projects are delayed, individuals' skills and talents aren't fully utilized, and the business is dissatisfied. In the past, IT's role was to keep systems running, but the new IT's role is to help the business gain customers, keep customers, gain revenue and improve profitability, all while still keeping systems running.

Identifying the tasks that may be more suited as-a-Service and removing them from the Full-time resource or team due to the two reasons stated will improve productivity and allow more resource time to go to strategic tasks. In addition, the team's senior level or advanced skills will be better utilized.

Increased elasticity to meet changing business

One of the major inputs driving JD Edwards EnterpriseOne CNC demand is business change. Seasonal changes, revenue growth, revenue decline, and business transformation all drive CNC demand. In a resource-based model or a monthly fixed-fee managed services model, meeting these changes takes both time and large amounts of increased costs. By the time the need is identified, resources recruited, contracts negotiated and changed, the business environment may be considerably different.

Meeting changing demand in real-time or near real-time is one of the strengths of an as-a-Service model.

The IaaS model is a good example. Amazon Web Services provides the ability to add the services of hundreds of servers in minutes. By comparison, doing the same in an On-Premise data center may take 6 months and considerable outlays of cash. Although much smaller in scope, CNC as-a-Service can provide the same. A service provider that offers a true as-a-Service model should be able to meet a significant amount of effort — doubling or more across a month of CNC demand, without any additional action being taken by the customer. The same would be true when CNC demand may decreases by half or more.

Increased transparency and signals for action

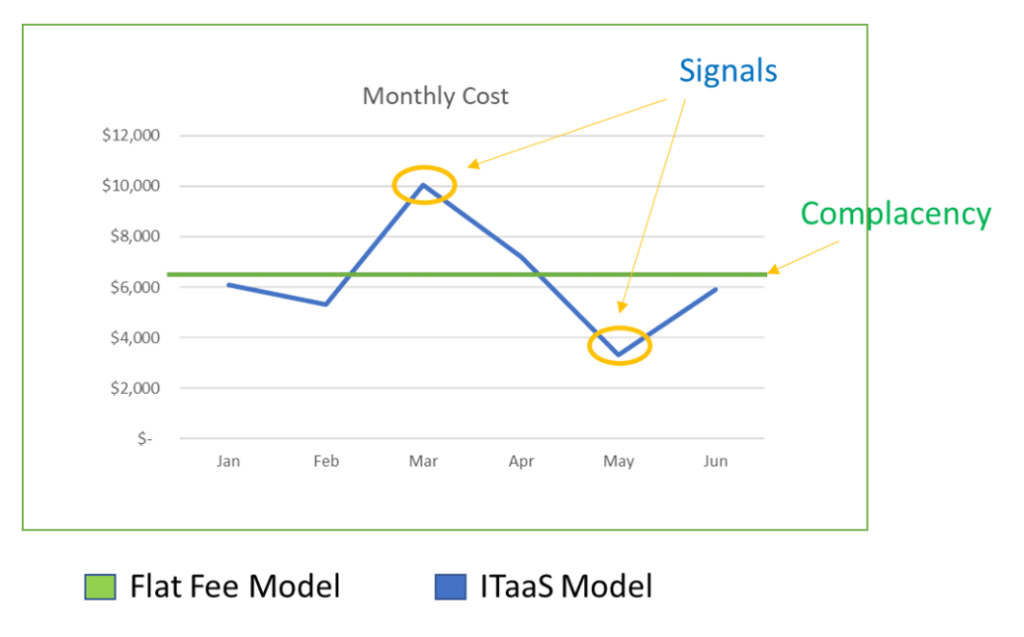

Signals are incredibly valuable. They alert you to make changes. Changes in money tend to be one of the strongest signals. In a resource-based model these signals may be missing. The cost of Full-time resource or a fixed monthly managed service offering are constant from month to month. The financial measures are typically salary, benefits or contract amount, rather than the actual time effort required to meet the demand. It's rare that an organization measures costs down to tasks. So on a month to month basis there is a comfort level. The signal to make changes are less visible.

Signals drive action.

In a true as-a-Service model these signals are always there as shown in the figure below. Because each month the customer is paying for services used; or in the case described in this blog, CNC services used, it will vary from month to month. Initially customers may feel this is a negative as they have to explain to their managers and financial teams. But if they step back and look at the big picture they will realize this is a big positive. When costs go down they are pleased and realize that there would have been waste in a fixed-cost scenario. When costs go up they have the ability to see why this is happening and make adjustments. In a true as-a-Service model every task should have a cost visible and transparent to the customer. This signal may allow them to determine if the service itself is of value — can it be streamlined, can it be automated, can it be eliminated, etc., all decisions which may not have even come onto the radar in a different model.

In closing, I'll provide an anecdote from my experience as a provider offering JD Edwards EnterpriseOne CNC services under both models. In a traditional model when the customer and I had recurring meetings set to discuss our ongoing services, quite regularly the customer would email to cancel a meeting due to other priorities. Under our Platform's as-a-Service funding model however, once they had received reporting during a month with particularly higher demand, I would promptly receive a request from the customer to review and discuss the data. They quickly realized after a few times the benefit of transparency and the signals for action that the model provides, even if it may be a little less comfortable in the beginning.

For more details or any queries, visit our online portal & know more about JD Edwards Database Administration & CNC Administration: www.allari.com

0