What is punching?

Punching is more than just making holes in sheet metal. Punching can create contours, form sheets and modify surfaces. And punching permits the complete machining of sheet metal parts.

Punching is a fast, efficient, productive and automated process and offers an enormous range of options.

What is a punching machine?

Punching machineis widely used in the stamping and forming of hardware parts such as electronics, communications, computers, household appliances, furniture, and transportation.

It is composed of two major components, i.e, die and punch. In operation, the punch pushes against the work-piece, which is held in the die.

A blanking die shears out a slug of sheet metal to make it into a blank that will fit dies for subsequent punch-press operations.

Detail About The Structure of a Punching Machine

- Punching head of the punching machine

The punching head is the heart of the punching machine. The punching head consists of the ram and the drive that moves the ram.

The ram is either driven hydraulically or electromagnetically and moves in the guide without wear. Only with an especially long ram guide the ram can also absorb high eccentric forces. This offers benefits when performing processing with beveled tools or with stepwise nibbling.

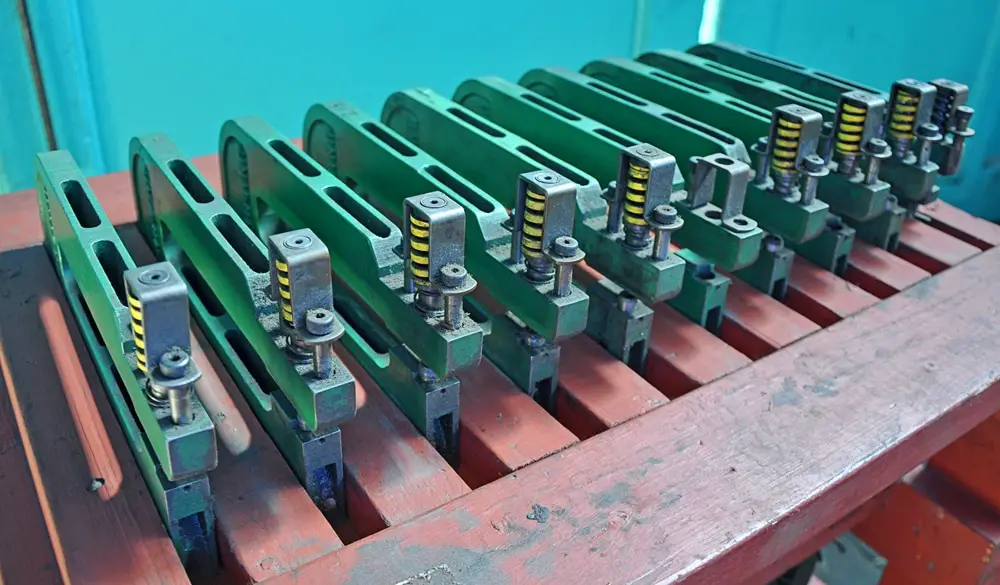

- Let’s talk about the tool set of punching machine

Tool set of punching machine includes:

Punches and die: Punches and dies make holes in sheet metal. Each punch installs into a manual or hydraulic punch press that forces it through the sheet metal and into a matching die. In a tool set the die is the counterpart to the punch. It counteracts the ram

force and permits punching.

Stripper: Stripper acts as a stripper on withdrawal of the punch, as a presser foot during punching with an active presser foot, and to hold the work-piece during repositioning.

- Alignment ring of the punching machines

The alignment ring has a pair of radially aligned cut outs, on its inner circumference and are on its out circumference.

A pin on the tool shaft engages the inner cut out to fix the tool against rotational movement relative to the ring. A second pin projects axially from the top of a punch point of the tool to engage the outer cut out.

- Frame of the punching machine

Punching machines can be designed with different frame shapes. For instance, a C frame punching machine.

The C-shaped design of the machine frame means that the machine is open at the front and readily accessible. For it is at the front that the working area is located.

Summary

Let’s conclude the article with the principle that punching machines follow.

The result of the punching process is not a continuous cut as seems the case when making holes in paper. Instead, the upper part of the material is cut by applying heavy force, pressing the punch onto the material, causing the lower part of the material to break off.

These machines are widely used in the manufacturing sector and thus, having a deep understanding of its structure is imperative. The above-mentioned points will help you in this pursuit.