When it comes to utilizing compressed air dryers, avoiding common mistakes can make a significant difference in their performance. Many individuals unknowingly fall prey to these errors, which can compromise the effectiveness of their desiccant and lead to subpar results.

By understanding and rectifying these blunders, you can ensure the optimal functioning of your compressed air dryer, maximizing its potential.

1. Choosing the Appropriate Desiccant

One of the most crucial aspects of utilizing compressed air dryers is selecting the right type of desiccants for your specific application.

Different desiccants possess distinct advantages and disadvantages, making it essential to make an informed decision. Consider factors such as moisture absorption capacity, efficiency, and compatibility with your compressed air dryer.

2. Timely Desiccant Replacement

Over time, desiccants become saturated with moisture and lose their ability to effectively dry the compressed air.

Failure to replace saturated desiccants can result in damp air, potentially causing damage to equipment downstream.

3. Proper Desiccant Bed Level

It is important to avoid the pitfall of overfilling the desiccant bed in your dryer. Overfilling can lead to restricted airflow, impeding the dryer's efficiency.

Ensure you fill the desiccant bed to the recommended level, allowing for unobstructed air passage. This enables efficient moisture removal and preserves the performance of your compressed air dryer.

4. Following the Manufacturer's Instructions

Manufacturers provide specific instructions on the usage and maintenance of desiccants and dryers. Neglecting these instructions can result in improper operation and reduced efficiency.

By adhering to the manufacturer's instructions, you guarantee the optimal functioning of your compressed air dryer and extend its lifespan.

5. Regular Dryer Inspection

Always check your dryer for damage, leaks, and other problems. Conduct thorough inspections to ensure all components are in good condition, and address any issues promptly.

Taking this preventative measure can ensure the safety and lifespan of your machinery.

By avoiding these common mistakes and implementing best practices, you can ensure that your compressed air dryer functions optimally, providing reliable and efficient drying capabilities.

Tips for Optimal Compressed Air Dryer Performance

In addition to avoiding common mistakes, here are some supplementary tips to enhance the performance of your compressed air dryer:

1. Compatibility: Ensure that the compressed air dryer desiccant you choose is compatible with your specific compressed air dryer model. Compatibility guarantees optimal performance and prevents any adverse effects on the drying process.

2. Desiccant Replacement: Follow the manufacturer's instructions regarding compressed air dryer desiccant replacement intervals. This ensures that the desiccant is always operating at its peak efficiency, maximizing its drying capacity.

3. Desiccant Bed Level: Maintain the correct desiccant bed level as recommended by the manufacturer. Proper bed level guarantees unimpeded airflow and maximizes the effectiveness of the desiccant.

4. Maintenance Guidelines: Strictly adhere to the manufacturer's maintenance guidelines. This includes regular cleaning, lubrication, and any other necessary procedures to keep your compressed air dryer in top shape.

5. Regular Inspections: Consistently inspect your dryer for signs of wear and tear, leaks, or other issues. By promptly addressing any problems, you prevent potential failures and extend the life of your equipment.

With these tips in mind, you can optimize the performance of your compressed air dryer desiccant, ensuring efficient drying and reliable operation.

Exploring Common Types of Compressed Air Dryer Desiccants

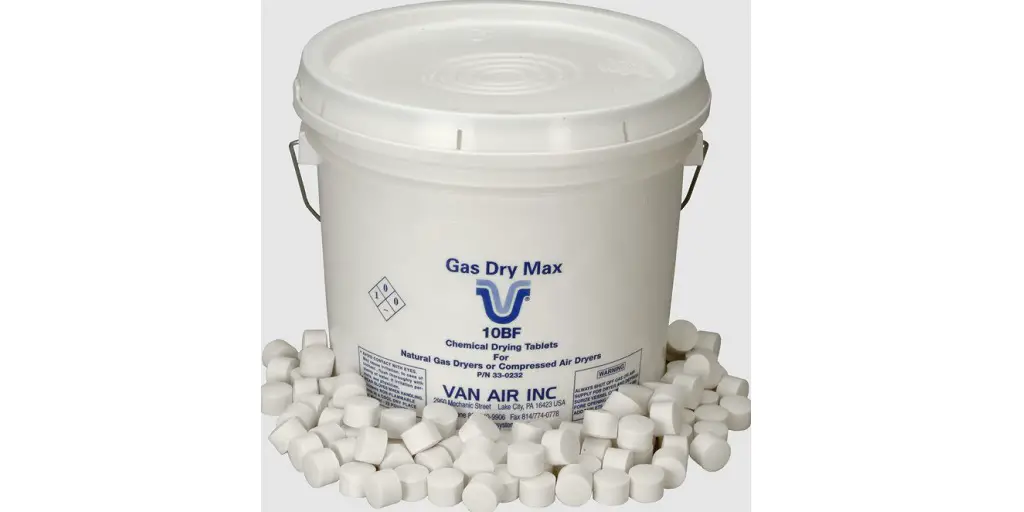

Now that you understand the importance of proper desiccant usage and maintenance, let's explore some common types of desiccants frequently used in compressed air dryers:

● Activated Alumina: Activated alumina possesses an increased surface area, making it highly efficient at absorbing moisture. This desiccant is ideal for applications that require exceptional moisture removal capabilities.

● Silica Gel: Silica gel consists of small, porous particles that effectively absorb moisture. Its versatility and high adsorption capacity make it a popular choice for various compressed air drying applications.

● Molecular Sieves: Molecular sieves are porous materials designed to absorb specific molecules, making them valuable in situations where targeted contaminant removal from the air is necessary.

Air & Vacuum Process Inc.: Your Desiccant Solution Provider

When it comes to acquiring high-quality compressed air dryer desiccants, Air & Vacuum Process Inc. is a trusted provider.

To learn more about compressed air dryers and desiccants or to place an order, please visit Air & Vacuum Process Inc.'s website or contact them at 866.660.0208.

You can maximize your compressed air dryer performance, longevity, and drying efficiency by following these guidelines. Take the necessary steps today and reap the rewards of a well-maintained and high-performing compressed air dryer.

For more information about Regenerative Desiccant Air Dryer and Silent Air Compressors Please visit: Air & Vacuum Process Inc.