A remote terminal unit (RTU) is a microprocessor-driven electronic device that tends to connect the objects in the physical world to a distributed control system or SCADA system by the transmission of the telemetry data to a master system and controlling all the connected objects via messages from the master supervision system. RTU is widely accepted as a Remote Telecontrol Unit or a Remote Telemetry Unit002E.

An RTU monitors digital and analogue parameters in the field and delivers data to a SCADA Master Station. It runs setup software to link data input and output streams, specify communication protocols, and troubleshoot installation issues in the field.

If you are looking for the best Remote Terminal Unit in Orissa, contact GroupNish today to avail the excellent RTU services.

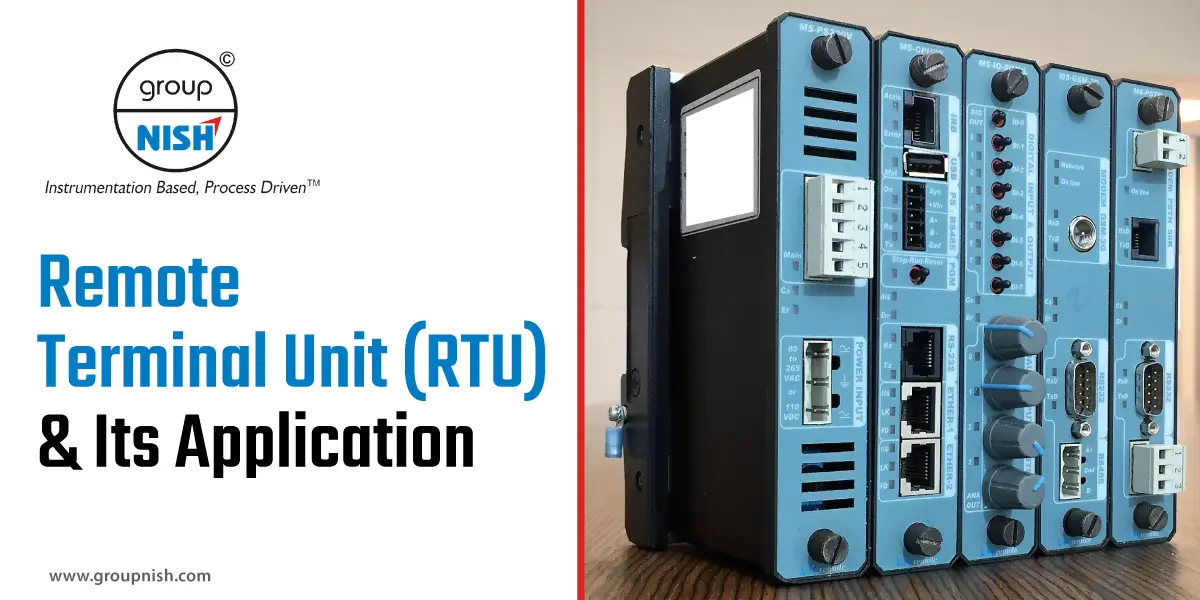

An RTU can be made up of a single complicated circuit card made up of multiple portions required to perform a custom-fitted function, or it can be made up of many circuit cards incorporating a CPU or processing with a communications interface(s) and one or more of the following: Analogue input (AI), digital (status) input (DI), digital (or control relay) output (DO/CO), or analogue output (AO) card (s).

An RTU could even be a small process control unit with a small database for PID, Alarming, Filtering, Trending, and other functions, as well as certain BASIC (programming language) duties. The IEC 61131-3 programming standard for programmable logic controllers is commonly supported by modern RTUs. Because RTUs are frequently installed in pipeline and grid guarding systems, as well as other difficult-to-reach or extreme areas, they must be able to operate in tough conditions and adopt energy-saving measures (such as switching off IO modules when not in use). In a multi-drop arrangement, for example, it interacts via RS485 or wireless communication lines. It is a remote unit that collects data and performs simple control duties in this sort of system. It has no moving parts, consumes very little power, and is frequently solar-powered.

Get the best-in-class Remote Terminal Unit with Cyber Security, only at GroupNish and leave all your Cyber Security worries behind.

Modern RTU:

Modern RTUs have a modular architecture with advanced data processing capabilities. Because of the modular RTU design variations, it can be used for installations ranging from a single point count site, such as a pole-mounted distribution transformer, to a high number of points in a big power substation. Expandable analogue input/output, digital input/output points, cumulative input units, and communication cards with power sources are all features of modern RTU modules. RTU installation requirements are satisfied by building the necessary number of RTU cards or rack-mounted modules to accommodate the analogue, control, digital, and communication links for supervisory control of the site.

For the distribution line need, the packing of an appropriate point count RTU is chosen. The SCADA for substation automation provides the option of installing one RTU in one cabinet with connections to the substation IEDs or establishing a master RTU and a number of slave RTUs at various places across the substation and connected to the master RTU via fibre-optic communications. The scattered RTU modules are combined to form a data concentrating unit, which communicates with the host SCADA computer system.

GroupNish offers the most efficient Remote Terminal Unit with cyber security in Orissa, India.

The excellent logic capability of RTU was used for algorithm creation to control the switched capacitors over the distribution feeder. When a zero voltage crossing occurs, the capacitors are turned on, and when a zero current crossing occurs, they are turned off. This algorithm can be programmed to switch the capacitors based on system parameters like voltage, power factor, reactive load, and time. The RTU's remote control feature enables the distribution operator to take control of the capacitors to fulfil the needs of inductive loads. Because of the aforementioned additional logic and input possibilities, the modern RTU has evolved into a dynamic device with expanded processing capabilities, uses, and applications.

For an industrialist, the Remote Terminal Unit with cyber security For Process house is one of the most essential must-have things to function smoothly without any cyber Security worries. To know more, visit the official website of GroupNish today.

Applications:

To monitor functions and instrumentation remotely, RTU is:

– Used for Oil and gas (onshore oil wells, offshore platforms, pump stations on pipelines)

– Used for Networking of pump stations (for wastewater collection, or water supply)

– Used for Environmental monitoring systems (to monitor air quality, pollution, emissions)

– Used for Mining sites

– Used for Air traffic equipment such as navigation aids (DME, ILS, DVOR, and GP)

– To monitor and control the functions and instrumentation remotely, RTU is:

– Used in Hydro-graphic systems (to check and control the water supply, reservoirs, sewage systems)

– Used in Electrical power transmission networks and associated equipment

– Used in Natural gas networks and associated equipment

– Used in Outdoor warning sirens.