A laser module is a device that emits laser beams of single or multiple wavelengths. People tend to confuse Laser modules and laser diodes, which are pretty different. One or more laser diodes combined with some optical and electron components make a laser module.

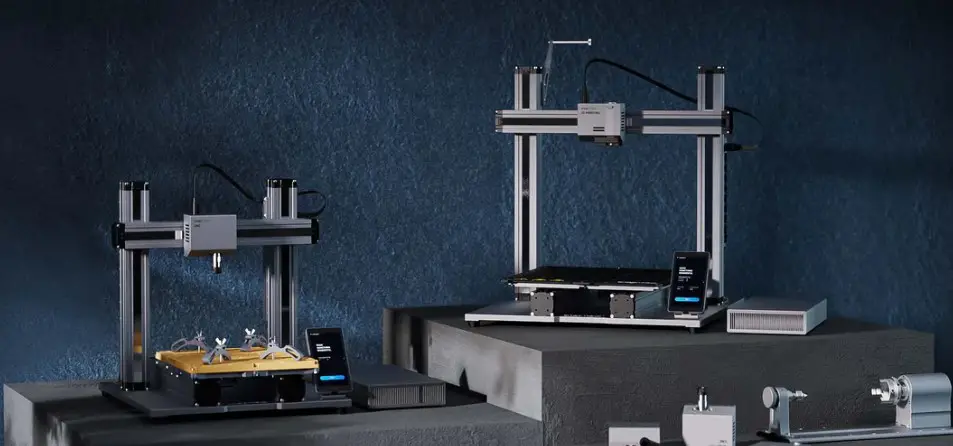

The 10W Snapmaker laser module is your number one go-to machine. It is a 3D laser cutter machine with a 10W high power. This new high-power laser machine is an add-on that supports more than 20 kinds of materials for engraving and more than 10 for cutting.

It is equipped with the most cutting-edge laser beam splitter effecting a power leap of between 5W and 10W, meaning you can now play with a broader scope of materials and make more exciting projects.

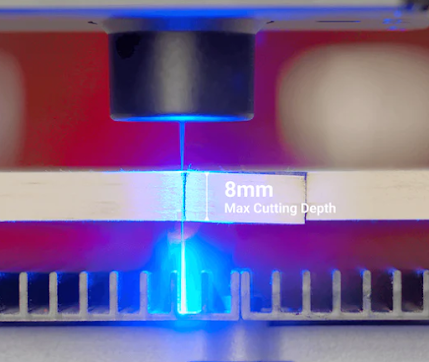

The work speed of this laser module for CNC can be as high as 6000mm/min while cutting through basswood as thick as 8mm, and its cutting speed is up to 8 times that of a 1600W Snapmaker laser module, fulfilling a laser job quicker than usual.

It has a Fast-axis collimating (FAC) lens set in the two laser diodes. First, the laser module for CNC compresses the laser spot of each laser diode. Then it combines the two laser beams of the two laser diodes using the beam combining technology, resulting in high power output and ultra-fine, which allows for higher energy density. Small laser focus and high power deliver high-quality work with faultless details.

This 3D laser cutter machine has a unique wind channel that provides superb wind pressure that blows the fumes away as the laser beam cuts into materials, sending the fumes directly into the grids of the laser engraving and cutting platforms, which then are taken out, reducing their interference on the laser machining.

When laser diodes are exposed to high temperatures, their lifespan reduces. The 10W laser module of CNC is equipped with two separate blowing systems for its PCBA and its laser diode to ensure the diode is properly cooled off whenever it is in use. When well used, the lifespan can be as long as 8,000-10,000 hours.

Thanks to the triangulation technique embedded in the 3D laser cutter machine, makers do not have to measure their materials manually. Instead, they just have to place their material on the platform, and the module will calculate it for them. The laser module can measure the thickness of the material by getting a few sets of data on the camera and light emitter. Then it will adjust itself in Z orientation so that the focal point falls right on the material surface. Focusing takes a few seconds to complete.

The wide-angle HD camera auto-focus and camera capture your material in one take and give you an instant preview of your laser job on the material in Luban, making your work completely hassle-free. Also, the Snapmaker software, Luban, helps you to work on your basic skills and master more sophisticated tricks, from simple image transformation to setting the correct parameters for different materials and cutting 3D models into cuttable laser vectors.

Furthermore, this module has a gyro sensor for safety purposes, ensuring that no a laser beam comes out if it is incorrectly installed or deviates from its designated position.

This 3D laser cutter machine is compatible with all Snapmaker 2.0 models apart from the 150 models and will be compatible with upcoming machines. Makers can also use it with other add-ons like the rotary module, emergency stop button, CAN Hub, and Air purifier.

As a caution, the 10W High power laser module should always be operated in a covered Snapmaker 2.0 enclosure since it's a class 4 laser product.