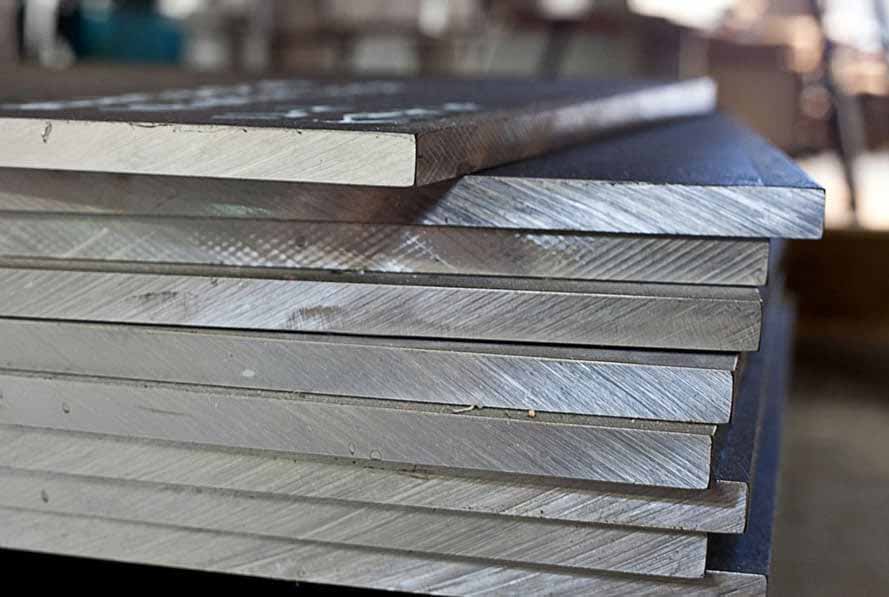

A steel plate, often known as structural steel, is essentially a stainless steel sheet board that may be cut and welded to create a more complex product. It is made by pressing many layers of steel together to form a steel plate. Structural Steel Plates are commonly used to reinforce structures and protect mass units such as bridges. Alternatively, it serves as a foundation for larger materials and non-workable parts. Steel Plate Systems places a high value on project specifics. This essentially means that some classes are more suited to certain activities than others.

The Advantages of Steel Plate

The Steel Plate is rust and abrasion-resistant. It is available in a significantly wider range of thicknesses than regular sheet steel. Plate steel is mostly utilized in applications requiring a super-structural structure and unbreakable toughness. It is designed not only for structural purposes but may also be used for basic repairs. Steel Plate can withstand immense tension from the toughest natural circumstances, particularly waves, and it also serves as an excellent reinforcing material. It is a huge help to the heavy machinery community. Its lifetime extends the life of wearing and machined components. Plate Steel has a high degree of flexibility, despite the fact that it is primarily used for strengthening and bracing.

Steel Plate Types

A pipe-shaped steel plate is a simple and common term for steel. Steel, on the other hand, can be alloyed with other metals to make them more resistant, heavier, or lighter to corrosion. The thickness will range from 3/16 inches to several inches depending on the steel plate alloy used. For example, the use of a steel plate by a pressure vessel may allow only 3/4-inch thickness, whereas military-grade anti-armor ammunition testing may require as much thickness as possible.

Applications of Steel plates.

Construction

The building business necessitates a wide range of steel sizes. Steel plates can be utilized in buildings, schools, and bridges. Stainless Steel 304 Plates are frequently used as structural steel covers in sports facilities, airports, prefabricated constructions, factories, railroad stations, and automobiles.

Marine

Stainless Steel 304L Plates are also widely used in the shipbuilding industry. The plates are used by ships and barges, as well as oil rigs and other offshore equipment. They could be used to make structural components or as repair parts. Steel plates with high tensile strength are sometimes required, notably in the construction of large offshore structures.

Vessels Under Pressure

A pressure vessel plate is a steel plate that is used for container storage. Such storage containers could be boilers, gas pumps, or any device that retains liquid gas or liquids. There are higher temperatures that can be produced to retain things at ambient temperatures or to transport material. Depending on the use, such steel plates might be coarse-grain or fine-grain.

Military

Higher-grade steel plates are also requested by the Defense Department for use in combat equipment and structures. Steel producers for military contracts adhere to the rules and specifications issued by the Defense Department and other branches such as the Army, Air Force, and Marine Corps. Combat steel plates are available for tanks, jeeps, buses, and land equipment, as well as planes, ships, and other aircraft. This steel is used by the Navy for military maintenance and shipbuilding.

0