Chamfer end mills are versatile cutting tools widely used in woodworking to achieve precise beveled edges and perform various other tasks. With their unique design and capabilities, these tools offer several advantages that contribute to the efficiency and quality of woodworking projects.

Let’s explore the different uses of chamfer end mills in woodworking, the types available, tips for effective usage, and safety precautions to keep in mind.

Chamfer End Mills in Woodworking

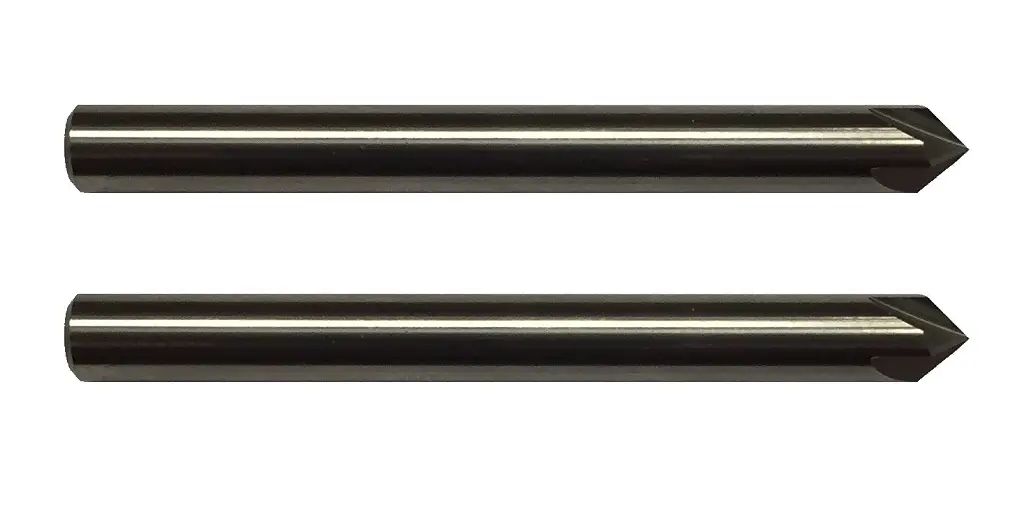

Chamfer end mills are milling cutters with cutting edges that have a specific angle, known as the chamfer angle. They are typically made of high-speed steel (HSS) or carbide and are available in various sizes and configurations to suit different woodworking applications.

These end mills can be used in milling machines or CNC routers to remove material and shape wood with precision.

Woodworking requires precision and attention to detail, and chamfer end mills are essential tools that help craftsmen achieve accurate results. These cutting tools feature angled cutting edges and are primarily used for creating beveled edges, chamfers, and other decorative details.

However, their utility extends beyond these specific tasks, making them invaluable in woodworking projects of various scales and complexities.

Types of chamfer end mills

Single-angle chamfer end mills

Single-angle chamfer end mills have a cutting edge with a constant chamfer angle throughout its length. These are commonly used for creating uniform beveled edges and chamfers of a specific angle.

Double-angle chamfer end mills

Double-angle chamfer end mills have two cutting edges with different chamfer angles. These versatile tools allow for more flexibility in creating different chamfer widths and angles, making them suitable for a wide range of woodworking tasks.

Advantages of using chamfer end mills in woodworking

Enhanced finishing

One of the primary advantages of using chamfer end mills in woodworking is the enhanced finishing they provide. The angled cutting edges help create smooth beveled edges, reducing the need for additional sanding or smoothing.

Improved chip evacuation

Chamfer end mills are designed with flutes that aid in chip evacuation during the cutting process. Efficient chip removal prevents clogging and ensures better cutting performance, leading to cleaner and more precise results.

Reduced tool wear

The chamfer angle of these end mills allows for a gradual entry into the wood, reducing the stress on the tool and minimizing wear. This feature contributes to the longevity of the tool, reducing the frequency of tool replacement and saving costs in the long run.

Versatility in woodworking applications

Chamfer end mills can be used for a wide range of woodworking tasks, including creating beveled edges, chamfers, and decorative details. They are suitable for various wood materials, such as solid wood, plywood, MDF, and more, making them versatile tools for different projects.

Common Woodworking Tasks

Chamfer end mills find applications in various woodworking tasks. Some common uses include:

Creating beveled edges

Chamfer end mills are ideal for creating precise beveled edges on wood pieces, adding a professional touch to furniture, cabinetry, and other woodworking projects.

Joinery and edge treatment

These end mills are effective in creating smooth edges for joinery, such as dovetail joints or tongue and groove connections. They can also be used for edge treatments, enhancing the visual appeal of the woodwork.

Adding decorative details

Chamfer end mills allow woodworkers to add decorative details to their projects, such as chamfered borders or intricate designs. These details can elevate the aesthetics of furniture, moldings, and other woodworking creations.

Chamfer end mills are invaluable tools in woodworking, offering precision and versatility for any craftsman. With their enhanced finishing capabilities, they contribute to the efficiency and quality of woodworking projects. Woodworkers can achieve outstanding results in their woodworking endeavors with these tools as part of their woodworking equipment.

For More Information about Carbide Cutting Tools and Single Pitch Thread Mills Please Visit : Online Carbide