Introduction

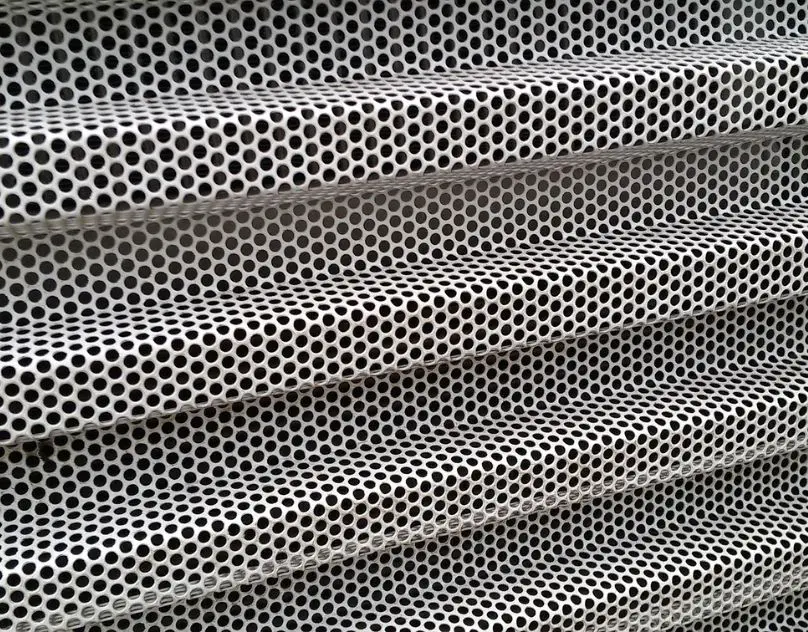

A perforated sheet is a metal sheet that has been treated to have a pattern of evenly spaced holes. The size, shape, and spacing of these holes might vary based on the application's unique needs. Perforated metal is made by punching or stamping holes into a sheet of metal using specialized accessories.

Sagar Steel Corporation is one of the leading Perforated Sheet Manufacturers in India.ASTM A240 has been conceived and developed in accordance with international and national quality standards. We are an ISO 9001:2008 accredited firm that has been in business since 2003. We provide our products at the most competitive pricing to all of our clients, with standard stock sizes, materials, and kinds available for rapid shipping globally.

Perforated metal sheets are often created from metals such as stainless steel, aluminum, brass, and carbon steel. The metal used is determined by considerations such as designed strength, corrosion resistance, and appearance.

Types Of Perforated Metal Sheet

Benefit Of Perforated Metal Sheet

In addition to their specific characteristics and mobility, perforated sheets provide several advantages. Here are a few main benefits of utilizing perforated sheets:

Enhanced Ventilation and Airflow : Perforated sheets allow air, gases, and liquids to pass through while preventing bigger particles from entering. This function is useful in applications that demand effective airflow and ventilation, such as HVAC systems, industrial equipment, and electronic enclosures.

Improved Filtering and Separation: Perforated sheet hole patterns may be customised to filter and separate materials based on their size. This is useful in applications such as sieves, strainers, and filtration systems where certain particles or impurities must be passed selectively.

Noise Reduction and Acoustic Control: Noise levels can be reduced and acoustics improved by using perforated metal sheets with precise hole designs. They are valuable in architectural applications such as auditoriums, music halls, offices, and manufacturing facilities because they can absorb or scatter sound waves.

Lightweight and Durable:Perforated sheets are often constructed of lightweight yet durable metals such as stainless steel, aluminum, or carbon steel. They offer structural strength while being lightweight, making them ideal for applications where weight is an issue, such as the aerospace, automotive, and marine sectors.

Aesthetic Appeal and Design Flexibility: Due to the arrangement of holes, perforated sheets have an aesthetically pleasant look and may be customized to produce distinctive visual effects. They are utilized to offer style and aesthetic appeal to areas in architectural design components, interior decorations, and artistic displays.

Increased Safety and Security:Perforated sheets can act as protective barriers while yet allowing for view and ventilation. Fencing, partitions, machine guards, and window grilles are examples of applications where safety and security are vital.

Overall, perforated sheets have several advantages, such as improved ventilation, filtering capabilities, noise reduction, design flexibility, and cost-effectiveness. Because of their adaptability, they are suited for a wide range of industries and applications.