Introduction:

Flanges are mechanical components used to connect pipes, valves, pumps, and other equipment in a piping system. They provide a means for joining two or more sections of pipe or equipment together and allow for easy disassembly and maintenance.

Here are some key features and aspects of flanges:

Connection:

Flanges create a secure and leak-tight connection between two or more pipes or equipment. They are typically bolted together, creating a strong and reliable joint.

Types:

Flanges come in various types, including slip-on flanges, weld neck flanges, socket weld flanges, threaded flanges, blind flanges, and lap joint flanges. Each type has specific characteristics and applications.

Material:

Flanges are commonly made from materials such as carbon steel, stainless steel, alloy steel, and even non-metallic materials like PVC (polyvinyl chloride). The choice of material depends on factors like the application, temperature, pressure, and corrosive environment.

Size and Pressure Ratings:

Flanges are available in different sizes, ranging from small diameters to large ones, to accommodate various pipe sizes. They also have pressure ratings, which indicate the maximum pressure the flange can withstand without failure.

Gasket:

Flanges require a gasket between the mating surfaces to ensure a proper seal and prevent leakage. Gaskets are usually made from materials like rubber, graphite, or PTFE (polytetrafluoroethylene).

Standards:

Flanges are manufactured to conform to specific standards to ensure compatibility and interchangeability. Common standards include ASME (American Society of Mechanical Engineers) B16.5, ASME B16.47, and API (American Petroleum Institute) 6A.

Flange Faces:

Flanges have mating surfaces called flange faces, which come in different configurations. The most common types are raised face (RF) and flat face (FF). The selection of the flange face type depends on factors like the application and the required level of sealing.

Applications:

Flanges are widely used in various industries, including oil and gas, chemical, petrochemical, power generation, water treatment, and HVAC (heating, ventilation, and air conditioning) systems.

Overall, flanges play a crucial role in piping systems by providing a secure, leak-tight, and easily maintainable connection between pipes and equipment. Their versatility and range of options make them essential components in numerous industrial applications.

Types of Flanges We Manufacture:

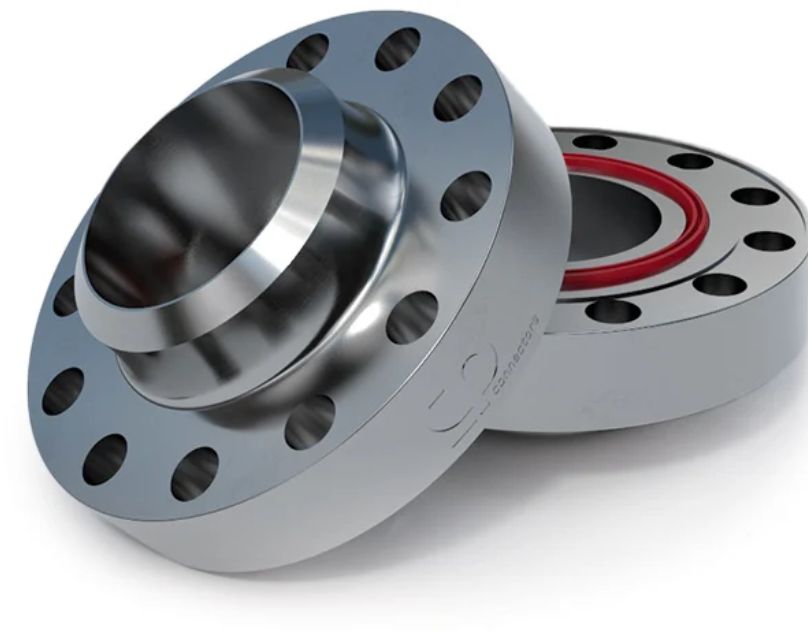

Hub Flanges:

Hub flanges are the elevated circular areas where spokes are attached to a bicycle hub. They are frequently composed of steel or aluminum, and they provide structural support for the wheel by distributing the spoke strain uniformly around the hub's diameter.

>Hub Flange Manufacturers in India

Without Hub Flanges:

some variations of bicycle wheel designs that do not have traditional hub flanges.

To mount a freewheel or fixed-gear cog, some single-speed and fixed-gear bicycles, for instance, utilize what is known as a “flip-flop” hub, which includes a threaded area on both sides of the hub. Instead of the more conventional raised flanges, these hubs could have a flat surface where the spokes are mounted.

>Without Hub Flange Manufacturers in India

Plate Flanges:

Plate flanges are a form of flange that are frequently used in industrial applications to connect pipes, valves, and other machinery. They consist of a flat, circular disc with evenly spaced bolt holes all the way around and are typically made of materials like carbon steel, stainless steel, or cast iron.

>Plate Flange Manufacturers in India

Slip on Flanges:

Slip-on flanges, a type of plate flange, are often used in industrial settings to join pipes, valves, and other gear. They are often made of materials like carbon steel, stainless steel, or cast iron and consist of a flat, circular disc with a borehole in the center and evenly spaced bolt holes around the circumference.

>Slip on Flange Manufacturers in India

Blind Flanges:

A blind flange, a kind of flange, is used to seal the end of a pipe, valve, or pressure vessel. They are designed to be attached to the end of the pipe or piece of machinery in order to create a tight seal that stops fluid or gas from escaping.

>Blind Flange Manufacturers in India

Socket Weld Flanges:

The end of one pipe is inserted into the socket of another to form a socket weld, which is a sort of pipe fitting used to connect two pipes. A sturdy and long-lasting connection between the two pipes is then created by welding the joint.

>Socket Weld Flange Manufacturers in India

You can also search for:

- Carbon Steel Flanges Vs Mild Steel Flanges

- Carbon Steel Flanges Manufacturer in India

- Carbon Steel Flanges Manufacturer in Navi Mumbai MIDC

- ASTM A350 LF2 Flanges Manufacturer in India

- Mild Steel Flanges Manufacturer in India

- Threaded Flanges Manufacturer in India

- MS Flange Manufacturer in Bhavnagar

Metalica Forging Inc. is one of India's reputed Flanges Manufacturers in India. Flange Steel Fittings are developed and produced in line with the IQS (International Quality Standards). We are also India's well-known Flanges Manufacturers.

Website: metalicaforginginc.com

For other information Flange Standard Dimensions.